熱鍍鋅電纜橋架和冷鍍鋅電纜橋架的五點區(qū)別

濟南電纜橋架中使用的大部分電纜橋架均為熱鍍鋅電纜橋架和冷鍍鋅電纜橋架。兩個電纜橋架的應用場景不同,導致工藝差異很大,但大多數消費者不知道有什么不同,只是讓用什么樣的就用什么樣的,增利來橋架給了我們做個科普,講解下目前使用的兩種電纜橋架的不同之處。

Most of the cable trays used in Jinan cable tray are hot-dip galvanized cable tray and cold-dip galvanized cable tray. The application scenarios of the two cable trays are different, resulting in great differences in processes, but most consumers don't know the difference. They just let us use what kind of cable tray to increase profits. They gave us a popular science and explained the differences between the two cable trays currently used.

熱鍍鋅電纜橋架和冷鍍鋅電纜橋架主要有以下五點區(qū)別:

There are five main differences between hot-dip galvanized cable tray and cold-dip galvanized cable tray:

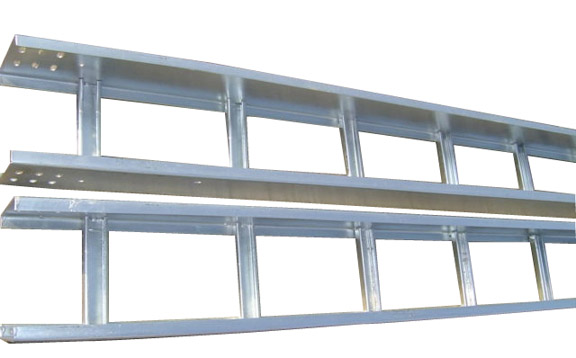

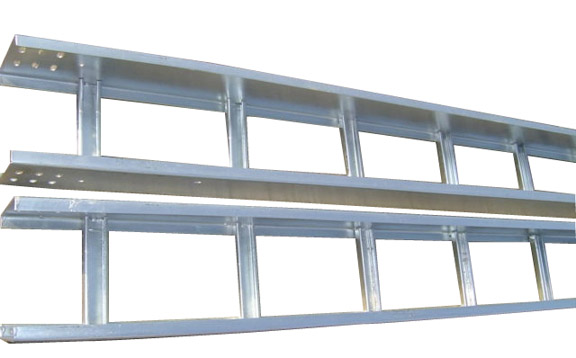

1.冷鍍鋅電纜橋架的工藝過程:將鋼材表面化學清洗處理后放進電鍍液中,電鍍液含氧化鋅。直流電一端接鋼材,一端接放在電鍍液中的鋅板。通電后鋅以分子狀態(tài)置換到鋼材表面。如果加光亮劑鈍化,則體現(xiàn)彩云狀光亮鍍層。

1. Process of cold galvanized cable tray: put the steel surface into the electroplating solution after chemical cleaning, and the electroplating solution contains zinc oxide. One end of the direct current is connected to the steel and the other end is connected to the zinc plate placed in the electroplating solution. After power on, zinc is replaced to the steel surface in molecular state. If the brightener is added for passivation, the color cloud like bright coating will be reflected.

2.熱鍍鋅電纜橋架的工藝過程:將鋼件或鑄件浸入熔融的鋅液中在其表面形成鋅 — 鐵合金或鋅和鋅 — 鐵合金覆蓋層的工藝過程和方法。

2. Process of hot-dip galvanized cable tray: the process and method of immersing steel parts or castings in molten zinc to form zinc ferroalloy or zinc and zinc ferroalloy coating on their surface.

3.熱鍍鋅橋架鍍層較厚,抗腐蝕能力較強。冷鍍鋅橋架鍍鋅層較熱鍍鋅橋架光亮,但較薄,抗銹蝕能力較弱。一般冷鍍鋅橋架是用熱鍍鋅板加工成橋架,而熱鍍鋅橋架是冷軋板先加工后熱鍍鋅成的。

3. Hot dip galvanized bridge has thick coating and strong corrosion resistance. The galvanized layer of cold galvanized bridge is brighter than that of hot galvanized bridge, but it is thinner and has weak corrosion resistance. Generally, the cold galvanized bridge is processed into a bridge with hot-dip galvanized plate, and the hot-dip galvanized bridge is processed first and then hot-dip galvanized with cold-rolled plate.

4.主要是生產工藝不同,熱鍍鋅橋架是在鋅鍋溶液中通過,冷鍍鋅橋架是通過電反應獲得。

4. The main reason is that the production process is different. The hot-dip galvanized bridge is obtained in the zinc pot solution, and the cold galvanized bridge is obtained by electric reaction.

5.應用在鋼結構上的電鍍鋅橋架一般防銹效果都不是很好,主要是鍍鋅量達不到,而且鍍鋅不均勻,一般兩三年就出現(xiàn)生銹現(xiàn)象,質量差的暴露在潮濕環(huán)境中十幾天就生銹了。

5. Generally, the anti rust effect of the electro galvanized bridge applied to the steel structure is not very good, mainly because the amount of galvanizing can not be reached, and the galvanizing is uneven. Generally, rust occurs in two or three years, and the poor quality will rust after being exposed to the humid environment for more than ten days.

通常,兩個不同的電纜橋架各有優(yōu)點,每個都適用于不同的場景。不能說熱鍍鋅橋架不好,或冷鍍鋅橋架不好,但了解兩個電纜橋架的不同之處也很有必要。

Generally, two different cable trays have their own advantages, and each is suitable for different scenarios. It can't be said that hot-dip galvanized bridge is bad or cold galvanized bridge is bad, but it is also necessary to understand the differences between the two cable bridges.

This article is provided by Shandong cable bridge. Our website is: http:// We will serve you with wholehearted enthusiasm. Welcome to visit

上一篇:如何判斷電纜橋架的故障?

下一篇:如何處理電纜橋架出現(xiàn)的靜電?

下一篇:如何處理電纜橋架出現(xiàn)的靜電?

相關文章 / Recommended news

梯式電纜橋架的優(yōu)缺點是什么

梯式電纜橋架的優(yōu)缺點是什么 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架