電纜橋架選購要點介紹

電纜橋架是由托盤式、槽式、梯級式的直線段、三通、四通、彎通以及吊架等構(gòu)成的具有密接支撐電纜的剛性結(jié)構(gòu)的統(tǒng)稱。

Cable tray is a general name of rigid structure with tight support cable, which is composed of tray type, trough type, step type straight section, tee, cross, bend and hanger.

現(xiàn)在市面上電纜橋架有很多,不同制作材料、不同類型的電纜橋架相差較大,那么我們在選購時要注意些什么呢?

There are a lot of cable trays on the market now. The prices of different materials and types of cable trays vary greatly. So what should we pay attention to when we buy them?

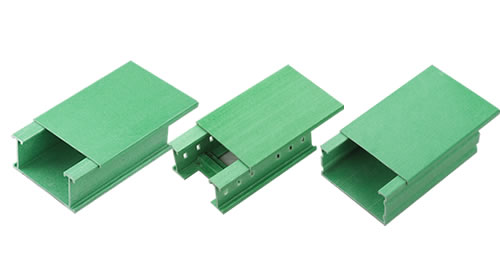

選購時要根據(jù)施工的工程環(huán)境和技術(shù)的要求,合理的選擇電纜橋架的結(jié)構(gòu)特征;電纜橋架按照材料劃分主要有玻璃鋼、鋼制和鋁合金幾種,玻璃鋼電纜橋架質(zhì)量輕,耐腐蝕性好,不易燃,適合化工廠,但是其是鋼制電纜橋架的3倍,在選擇時要根據(jù)具體用途,選擇不同材質(zhì)的電纜橋架。

When purchasing, first of all, according to the engineering environment and technical requirements of the construction, the structural characteristics of the cable tray should be reasonably selected; according to the material, the cable tray is mainly divided into FRP, steel and aluminum alloy. The FRP cable tray is light in weight, good in corrosion resistance, nonflammable and suitable for the factory, but its price is three times that of the steel cable tray, so the selection should be based on the specific use , select cable tray of different materials.

電纜橋架的表面防腐層類別主要有浸鋅、粉末靜電噴涂、鍍鋅鎳、冷鍍鋅等方式,熱浸鋅工藝生產(chǎn)的電纜橋架使用壽命不小于40年,適用于室外重腐蝕環(huán)境,造價高;粉末靜電噴涂工藝壽命不小于12年,適用于室內(nèi)常溫干燥環(huán)境,一般;鍍鋅鎳工藝壽命不小于30年,也適用于室外重腐蝕環(huán)境,造價高。

The types of surface anti-corrosion coating of cable tray mainly include zinc dipping, powder electrostatic spraying, galvanized nickel, cold galvanizing, etc. the service life of cable tray produced by hot-dip galvanizing process is not less than 40 years, which is suitable for outdoor heavily corrosive environment with high cost; the service life of powder electrostatic spraying process is not less than 12 years, which is suitable for indoor normal temperature and dry environment with general price; the service life of galvanized nickel process is not less than 30 years It is also suitable for outdoor heavy corrosive environment with high cost.

上一篇:電纜橋架的規(guī)格如何選擇?

下一篇:符合電纜橋架接地干線回路的條件是什么?

下一篇:符合電纜橋架接地干線回路的條件是什么?

相關(guān)文章 / Recommended news

梯式電纜橋架的優(yōu)缺點是什么

梯式電纜橋架的優(yōu)缺點是什么 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架