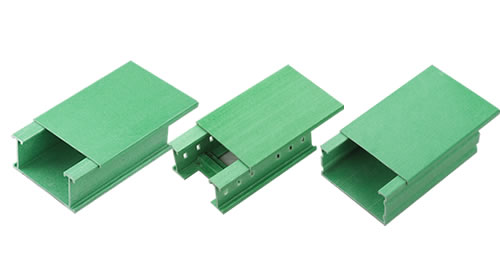

噴塑橋架和鍍鋅橋架的區(qū)別介紹

工程中電纜橋架是電氣安裝常用的材質(zhì)設(shè)施,以敷設(shè)線纜多施工方便而優(yōu)于管道,尤其在系統(tǒng)干線,集中布線的場合更加體現(xiàn)其優(yōu)越性。橋架的形式有槽式托盤式梯架式等多種。橋架也有很多種材質(zhì)和不同類型的工藝,比如材質(zhì)分為:不銹鋼鋁合金玻璃鋼等材質(zhì);工藝分為:熱鍍鋅靜電噴塑鍍鋅等工藝;另外按消防要求還有防火與耐火的橋架。每種材質(zhì)和工藝的性能特點(diǎn)都是不同的,電纜橋架主要用途是用來支撐電纜保護(hù)電纜以及管理電纜的,給我們的電纜線路管理帶來了很大的方便。

Cable trays are commonly used materials and facilities for electrical installation in engineering, which are superior to pipelines due to the convenience of laying multiple cables. Especially in the case of system trunk lines and centralized wiring, their superiority is reflected. There are various forms of cable trays, such as slot type tray type ladder type. There are also many types of materials and processes for cable trays, such as stainless steel, aluminum alloy, fiberglass, and other materials; The process is divided into: hot dip galvanizing, electrostatic spraying, galvanizing, and other processes; In addition, according to fire protection requirements, there are fire resistant and fire-resistant cable trays. The performance characteristics of each material and process are different, and cable trays are mainly used to support cable protection cables and manage cables, bringing great convenience to our cable route management.

鍍鋅橋架:

Galvanized cable tray:

鍍鋅橋架又名電鍍鋅橋架;一般人理解為鍍鋅橋架以為是熱鍍鋅橋架,其實(shí)是不對的,跟鍍鋅管一樣,橋架的鍍鋅也分兩種,即冷鍍鋅(電鍍鋅和熱鍍鋅(熱浸鍍鋅;

Galvanized cable tray, also known as galvanized cable tray; It is generally understood that galvanized cable trays are considered hot-dip galvanized, but it is actually incorrect. Like galvanized pipes, there are two types of galvanizing for cable trays: cold galvanizing (electro galvanizing) and hot galvanizing (hot dip galvanizing);

鋼鐵在空氣水或土壤中很容易生銹,甚完全損壞。每年因腐蝕造成的鋼鐵損失約占整個(gè)鋼鐵產(chǎn)量的1/10,另一方面,為使鋼鐵制品與零件表面具有某種特殊功能,同時(shí)賦予其表面裝飾性的外觀,所以,一般采用電鍍鋅的方式對其處理。

Steel is prone to rust and even complete damage in air, water, or soil. The annual steel loss caused by corrosion accounts for about 1/10 of the entire steel production. On the other hand, in order to give steel products and parts a special function on the surface and give them a decorative appearance, electroplating is generally used to treat them.

原理:

Principle:

由于鋅在干燥空氣中不易變化,而在潮濕的空氣中,表面能生成一種很致密的堿式碳酸鋅薄膜,這種薄膜能有效保護(hù)內(nèi)部不再受到腐蝕。并且當(dāng)某種原因,使鍍層發(fā)生破壞而露出不太大的鋼基時(shí),鋅與鋼基體形成微電池,使鋼基體成為陰極而受到保護(hù)。

Due to the fact that zinc is not easily changed in dry air, and in humid air, a dense alkaline zinc carbonate film can be formed on the surface, which can effectively protect the interior from corrosion. And when for some reason, the coating is damaged and a relatively small steel substrate is exposed, zinc forms a micro battery with the steel substrate, making the steel substrate a cathode and protected.

性能特點(diǎn):

Performance characteristics:

鋅鍍層較厚,結(jié)晶細(xì)致均勻且無孔隙,抗腐蝕性良好;

The zinc coating is thick, with fine and uniform crystallization without pores, and has good corrosion resistance;

電鍍所得鋅層較純,在酸堿等霧氣中腐蝕較慢,能有效保護(hù)鋼基體;

The zinc layer obtained from electroplating is relatively pure and corrodes slowly in acid and alkali mist, which can effectively protect the steel substrate;

鋅鍍層經(jīng)鉻酸鈍化后形成白色彩色軍綠色等,美觀大方,具有一定的裝飾性;

The zinc coating is passivated with chromic acid to form white, colorful military green, etc., which is beautiful and elegant, and has a certain degree of decoration;

由于鋅鍍層具有良好的延展性,因此可進(jìn)行冷沖軋制折彎等各種成型而不損壞鍍層。

Due to the excellent ductility of zinc coating, it can be formed through various processes such as cold stamping, rolling, and bending without damaging the coating.

應(yīng)用范圍:

Application scope:

隨著科學(xué)技術(shù)生產(chǎn)的發(fā)展,電鍍工業(yè)所涉及的領(lǐng)域越來越廣泛。目前,電鍍鋅的應(yīng)用已遍及國民經(jīng)濟(jì)的各個(gè)生產(chǎn)和研究部門。例如,機(jī)器制造電子精密儀器化工輕工交通運(yùn)輸兵器航天原子能等等,在國民經(jīng)濟(jì)中有重大意義。

With the development of scientific and technological production, the electroplating industry involves an increasingly wide range of fields. At present, the application of electrogalvanizing has spread to various production and research departments of the national economy. For example, machine manufacturing, electronic precision instruments, chemical industry, light industry, transportation, weapons, aerospace, atomic energy, etc., have significant significance in the national economy.

本文由山東電纜橋架友情奉獻(xiàn).更多有關(guān)的知識(shí)擊:http://我們將用真誠的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請期待.

This article is dedicated by Shandong Cable Bridge Friendship. More relevant knowledge is available: http:// We will provide you with comprehensive services with a sincere attitude. We will gradually contribute more relevant knowledge to everyone. Stay tuned

上一篇:電纜橋架的類型影響著具體的功能

下一篇:濟(jì)南鍍鋅電纜橋架施工要點(diǎn)

下一篇:濟(jì)南鍍鋅電纜橋架施工要點(diǎn)

相關(guān)文章 / Recommended news

梯式電纜橋架的優(yōu)缺點(diǎn)是什么

梯式電纜橋架的優(yōu)缺點(diǎn)是什么 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架