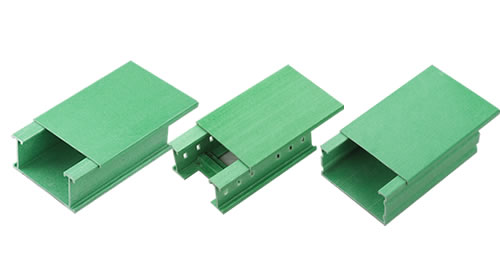

電纜橋架和附件應(yīng)選擇經(jīng)過防腐處理

電纜橋架和附件應(yīng)選擇經(jīng)過防腐處理的定型產(chǎn)品,其型號(hào)和規(guī)格應(yīng)符合規(guī)劃要求。可采用圓鋼、扁鋼、角鋼等制作橋架支架,大型電纜橋架可采用槽鋼制作。支架締造后應(yīng)進(jìn)行除銹,刷防銹漆。

Cable tray and accessories shall be anti-corrosion products, and their models and specifications shall meet the planning requirements. It can be made of round steel, flat steel and angle steel, and large cable tray can be made of channel steel. The bracket should be derusted and painted with antirust paint after it is built.

電纜橋架支吊架締造裝置:電纜橋架架體直立裝置時(shí),先將上端支架固定好,然后用線錘在中線處吊線,下端支架可按吊線均勻固定。電纜橋架水安定裝時(shí),能先將兩端固定好,再以兩端支座為基準(zhǔn)采用拉線法均勻安裝支座。

Cable tray support and hanger making device: when the cable tray body is upright, the upper bracket shall be fixed first, and then the wire hammer shall be used to hang the wire at the middle line, and the lower bracket can be fixed evenly according to the hanging wire. When the cable tray is installed in water, the two ends can be fixed first, and then the supports at both ends can be used as the benchmark to install the supports evenly with the pulling wire method.

濟(jì)南電纜橋架

濟(jì)南電纜橋架

橋架水安定裝時(shí),在首部、中部、端部等適當(dāng)位置添加防晃架。采用預(yù)埋鐵件焊接固定,焊縫飽滿。伸縮螺栓固定正時(shí),選擇螺栓配合,緊固相結(jié)合。

When the bridge is installed stably, the anti sway frame shall be added at the head, middle, end and other appropriate positions. The embedded iron parts are welded and fixed, and the welding seam is full. When the telescopic bolt is used to fix the timing, the bolt matching and fastening are selected.

電纜橋架有豐富的光纜分布環(huán)境。在各種電氣環(huán)境下,電纜塔板有多種型號(hào),以確保傳輸線。在架設(shè)電纜、支撐和發(fā)射高壓電纜、保護(hù)線路等起到重要作用。

The cable tray has abundant optical cable distribution environment. In a variety of electrical environments, cable tray has a variety of models to ensure the transmission line. It plays an important role in erecting cables, supporting and launching high-voltage cables, protecting lines, etc.

對(duì)這一問題,我們所熟知的表面工藝上進(jìn)行了冷熱鍍鋅、靜電處理、防火材料涂層等處理,使得不同的電纜橋架具有不同的實(shí)用價(jià)值,適合于更為嚴(yán)格的電氣施工環(huán)境。

To solve this problem, we are familiar with the surface technology of cold and hot galvanizing, electrostatic treatment, fireproof material coating treatment, so that different cable tray has different practical value, suitable for more stringent electrical construction environment.

上一篇:電纜橋架的分類特色介紹

下一篇:電纜橋架碰到短路問題怎么辦

下一篇:電纜橋架碰到短路問題怎么辦

相關(guān)文章 / Recommended news

梯式電纜橋架的優(yōu)缺點(diǎn)是什么

梯式電纜橋架的優(yōu)缺點(diǎn)是什么 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架