電纜橋架上的電纜簡單老化的六大原因剖析

電纜橋架上的電纜簡單老化的六大原因剖析

Analysis of six main reasons for simple aging of cables on cable tray

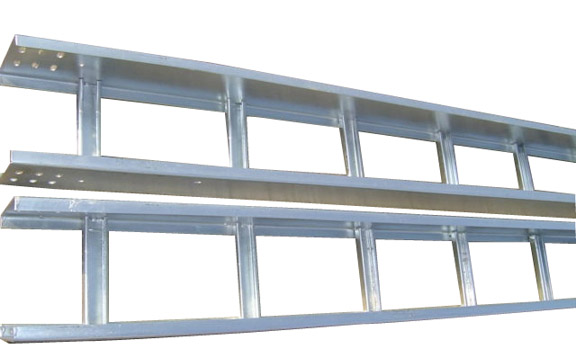

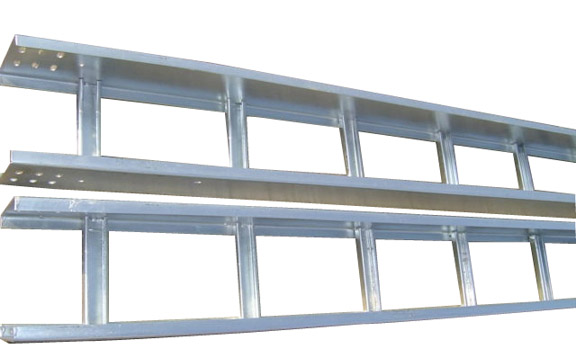

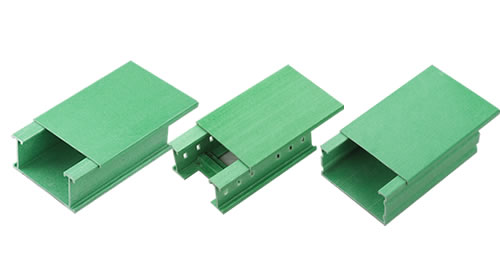

在線路敷設(shè)工程中,電纜橋架是一種很重要的隸屬設(shè)備,主要是擔任起到一個輔佐合理布線而且長時間維護線路的效果,一般狀況下電纜橋架上的線纜全賴外面的絕緣層,假如這層表皮損壞后絕緣功能將會下降許多,接下來我們就來說一下電纜橋架上的電纜簡單老化的六大原因吧。

Cable bridge is a very important subordinate equipment in line laying engineering. It mainly serves as an assistant for reasonable wiring and long-term maintenance of the line. In general, the cable on the cable bridge depends on the external insulation layer. If this layer of skin is damaged, the insulation function will drop a lot. Next I Let's talk about the six main reasons for the simple aging of cables on the cable tray.

1.絕緣受潮狀況;一般這樣的狀況也相對常見,一般發(fā)作在直埋或排管里的電纜接頭處。比方:電纜橋架上的電纜接頭制造不合格和在濕潤的氣候條件下做接頭,會使接頭進水或混入水蒸氣,在電場效果下構(gòu)成水樹枝,逐漸危害電纜的絕緣強度而構(gòu)成毛病。

1. Insulation damp condition; generally this kind of condition is relatively common, usually occurs in the direct buried or row pipe cable junction. For example, if the cable joints on the cable bridge are fabricated unqualified and made in wet climates, the joints will enter water or mix with water vapor, forming water branches under the electric field effect, gradually endangering the insulation strength of the cable and forming defects.

2.化工原料的腐蝕;電纜直接埋在有酸堿效果的區(qū)域,往往會構(gòu)成電纜的鎧裝.鉛皮或外護層被腐蝕,維護層因長時間遭受化學腐蝕或電解腐蝕,致使維護層失效,絕緣下降,也會導致電纜毛病。

2. Corrosion of chemical raw materials; Cables buried directly in areas with acid and alkali effects, often constitute the armor of the cable. Lead skin or outer protective layer is corroded, the maintenance layer due to long-term chemical corrosion or electrolytic corrosion, resulting in failure of the maintenance layer, insulation decline, also lead to cable defects.

3.長時間過負荷運轉(zhuǎn);超負荷運轉(zhuǎn),因為電流的熱效應(yīng),負載電流經(jīng)過電纜時必定導致導體發(fā)熱,一起電荷的集膚效應(yīng)以及鋼鎧的渦流損耗.絕緣介質(zhì)損耗也會產(chǎn)乍附加熱量,然后使電纜溫度升高。長時間超負荷運轉(zhuǎn)時,過高的溫度會加快絕緣的老化,以絕緣被擊穿。尤其在酷熱的夏日,電纜橋架的溫升常常導致電纜絕緣單薄處首要被擊穿,因此在夏日,電纜的毛病也就特別多。

3. Long-term overload operation; overload operation, because of the thermal effect of current, load current through the cable must lead to conductor heating, together with the skin effect of charges and steel armor eddy current loss. Dielectric loss will also produce additional heat, and then make the cable temperature rise. Over a long period of time, excessive temperature will accelerate the aging of insulation and even breakdown of insulation. Especially in the hot summer, the temperature rise of the cable bridge often causes the thin insulation of the cable to be first broken down, so in the summer, cable problems are particularly numerous.

4.電纜接頭毛病;電纜接頭是電纜線路中單薄的環(huán)節(jié),由人員直接過錯(施工不良)引發(fā)的電纜接頭毛病時常發(fā)作。施工人員在制造電纜接頭過程中,假如有接頭壓接不緊.加熱不充分等原網(wǎng),都會導致電纜頭絕緣下降,然后引發(fā)事端。

4. Cable joint faults; Cable joint is a thin link in the cable line. Cable joint faults caused by personnel's direct fault (bad construction) often occur. In the process of making cable joints, if the joints are not pressed tightly and the original network is not heated sufficiently, the insulation of the cable head will drop, and then cause an accident.

5.環(huán)境以及溫度因素;電纜橋架以及線纜周邊的外界環(huán)境和熱源也會構(gòu)成電纜溫度過高.絕緣擊穿,嚴峻的構(gòu)成爆破起火。

5. Environment and temperature factors; the external environment and heat sources around the cable bridge and cable will also constitute the cable temperature is too high. Insulation breakdown, severe composition of explosion and fire.

6.外力損害。當時的十分多的電纜毛病均以機械損害引起的居多。舉個例子看:電纜敷設(shè)裝置時不標準施工,簡單構(gòu)成機械損害;在直埋電纜上搞土建施工也極易將運轉(zhuǎn)中的電纜損害等。有的狀況下當時線纜的損害不嚴峻,可能需求幾個月乃幾年才可能會呈現(xiàn)損害部位徹底擊穿構(gòu)成毛病,還有的線纜損壞較重的可能發(fā)作短路毛病,直接影響電纜橋架和用電單位的生產(chǎn)日子保障問題。

6. external force damage. At that time, a lot of cable faults were mostly caused by mechanical damage. For example, cable laying device is not standard construction, which simply constitutes mechanical damage; civil construction on directly buried cable is also very easy to damage the cable in operation. In some cases, the damage to the cables was not serious, it may take several months or even years for the damaged parts to be completely broken down, and the damaged parts of the cables may be seriously short-circuit fault, which will directly affect the production of the cable bridge and the production of electricity supply unit.

Jinan Hangfeng Industry Co., Ltd., Shandong cable bridge friends can pay attention to our http://, please look forward to more exciting content.

上一篇:電纜橋架母線槽裝置用在什么地方

下一篇:電纜橋架施工裝置關(guān)鍵

下一篇:電纜橋架施工裝置關(guān)鍵

相關(guān)文章 / Recommended news

梯式電纜橋架的優(yōu)缺點是什么

梯式電纜橋架的優(yōu)缺點是什么 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架