熱鍍鋅橋架和鍍鋅橋架制作工藝上的區(qū)別

1、冷鍍鋅托盤(pán)的過(guò)程:清洗鋼材表面化學(xué)處理為電鍍液后,鍍含有氧化鋅溶液。直流一極,以鋼鐵,一極對(duì)鋅板電鍍液。

1, cold galvanized tray process: cleaning steel surface chemical treatment for electroplating solution, plating with Zinc Oxide solution. DC pole to steel, a pair of zinc plate plating solution.

通電后鋅以分子狀態(tài)置換到鋼材表面。如果添加光亮劑鈍化反映云彩像光亮鍍層。

When the power is turned on, the zinc is displaced to the surface of the steel by molecular form. If the brightener is added, the passivation reflects the clouds as bright as the coating.

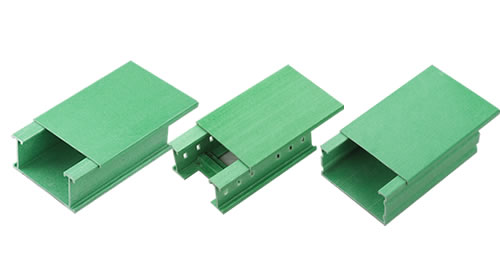

2、熱鍍鋅橋架的工藝過(guò)程:將鋼件或鑄件浸入熔融的鋅液中在其表面形成鋅 — 鐵合金或鋅和鋅 — 鐵合金覆蓋層的工藝過(guò)程和方法。熱浸鍍鋅層較厚,抗腐蝕能力強(qiáng)。熱鍍鋅鋅層過(guò)冷光源,但更薄,防銹能力較弱。

2. The process of hot-dip galvanizing bridge: the process and method of forming a zinc iron alloy or zinc and zinc iron alloy coating on the surface of molten steel by dipping steel or casting into molten zinc bath. Hot-dip galvanized layer is thicker and corrosion resistant. Hot galvanized zinc layer over cold light source, but thinner and less rust preventive ability.

3、主要生產(chǎn)不同的工藝,熱鍍鋅電纜橋架是在鋅鍋溶液中通過(guò),電鍍鋅橋架則是通過(guò)電極反應(yīng)得到。

3 、 the main production of different processes, hot galvanized cable bridge is in the zinc pot solution through, the zinc plating bridge tray is obtained by electrode reaction.

4、應(yīng)用在鋼結(jié)構(gòu)上的電鍍鋅橋架一般防銹效果都不是很好,小于主要鍍鋅量,和鍍鋅不均勻通常兩三年都出現(xiàn)生銹,質(zhì)量差的暴露在潮濕環(huán)境中十幾天就生銹了。

4, the application in steel structure of electro galvanized bridge general antirust effect is not very good, mainly less than galvanized and galvanized uneven, usually two or three years appear rust, the poor quality of the exposure in the humid environment of ten days rust.

客戶的滿意就是對(duì)我們的肯定,歡迎您前來(lái)選購(gòu)我公司的產(chǎn)品,我們一直以為您提供產(chǎn)品為己任并一直堅(jiān)持這樣做。歡迎您的光臨。

Customer satisfaction is our affirmation, you are welcome to come to buy our products, we have always thought you provide products as their own responsibility, and has always insisted on doing so. Welcome to our company.

上一篇:電纜橋架安裝的現(xiàn)場(chǎng)要求

下一篇:型橋架提高了利用率的使用

下一篇:型橋架提高了利用率的使用

相關(guān)文章 / Recommended news

梯式電纜橋架的優(yōu)缺點(diǎn)是什么

梯式電纜橋架的優(yōu)缺點(diǎn)是什么 安裝橋架

安裝橋架 安裝橋架

安裝橋架 安裝橋架

安裝橋架 防火橋架

防火橋架